|

99 Jspec License Plate Holder Shaving |

Article Date: 11-27-06

Author:

My

Fairlady Z

Mod Class: Z32 NA or TT w/ 99 Jspec Bumper

Mod Type: Cosmetic

Article Origin:

www.300zxclub.com

Difficulty Level: 7 (Scale of 1 to 10. 1 being extremely easy, 10 being extremely

difficult.)

Estimated Time to Complete: 3-5 days (Actual work time: 5-10 hours)

Tools Required:

- Cutting Wheel

- Masking Tape/Razor Blade

- Caulk gun for Urethane Epoxy

Materials Required:

- Jspec Bumper

- 'Cool Blue' Urethane Epoxy (I suppose Marine Tex also)

- Fiberglass strips (I'm guessing that's what you call it)

- 240 wet/dry sand paper (5-6 sheets)

- 500 wet sand paper (1-2 sheets)

- Automotive Primer (Grey)

- Guide Coat (Black - optional)

Estimated Cost:

- $50.00 ~$100.00 |

First Step: Cutting the Bracket Off

- I know it can make a z32 enthusiast cringe at even considering cutting into

their brand new $600 bumper. However, patience is key when you are beginning

this stage. You are going to want to cut the bracket into two sections.

First, cut along the red line (there is a pretty nice distinct line to cut along

from where you actually mount your license plate bracket compared to where it

connects with the body, you will see what I am talking about when you begin this

step.) You want to be pretty careful when doing this considering you are going

to be using this flat rectangular piece as filler. Hints, the more you save of

this "red" piece, the less epoxy you in turn have to use.

Once the front of the license bracket is off, you can now start cutting off

where it connected to the body. Be careful, you only want to cut right where it

meets the actual structure. If you cut more, you are going to have to use more

epoxy which = more $$$.

OPTIONAL: There is a piece that hangs in the opening of the "mouth" of the

bumper. It is rectangular with holes in it, I chose to leave it there so I could

mount my license plate there.

NOTE: Wear gloves, sweatshirt, goggles, oxygen mask. The urethane comes off VERY

hot and emits some sort of gas that will make your eyes and lungs burn.

Second Step: Filling the Hole (lol, I'm dirty)

Now that you have a big gapping hole in your brand new bumper, you can begin to

fill it in. Now, there are holes in the license plate bracket that you first

must address before ANYTHING else. Remember the green piece that you cut off?

These little strips will work PERFECT for filling in these holes/rectangles (see

above picture for reference on holes.) Insure these are snug when they fit in,

or they will just fall right out. I suggest you use that same bench grinder and

a razor blade to shape the pieces. You will then bend the "red" piece (flat,

rectangular piece with the holes that you just filled, dummy) so it follows the

curve on the bumper. This sounds scary, but it only takes 5 seconds and another

persons eye to tell you when it looks about right. Remember, if it isn't exactly

perfect you can always build it up with epoxy and primer.

Once you have this down, you can then begin laying the fiberglass strips down

and putting 'Cool Blue' Urethane Epoxy on it. You can then hold it in place with

masking tape, or you can sit there for the 12 hours for the epoxy to cure

completey. I suggest putting more on every 6-8 hours until it is held in

completely. I also suggest at least 2-3 coats of epoxy with sanding in between.

This is what it should look like.

Then after the coats of urethane (this is 2nd coat).

*NOTE: I didn't put the filler holes until after I had it on the bumper, I

suggest doing it off because it is easier to work with.

Third Step: Prime, Sand, Repeat.

Now, this is the FUN part. Once urethane coats are applied, you can block the

urethane smooth with 240 wet/dry sand paper to ensure no high/low spots. You

will do this with my weapon of choice: a paint stirrer. Just wrap sand paper at

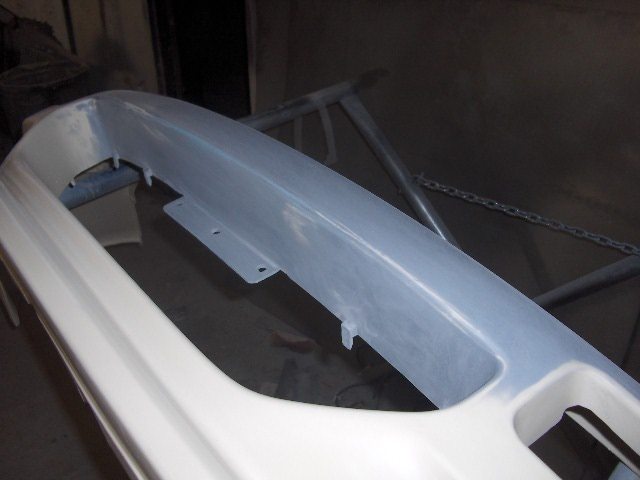

it and go at it. It should look like this right before the primer stage:

Once you're ready to primer, you want lay down about 5-6 coats. Then block with

240 wet/dry sand paper. You will do this as many times as needed until there are

NO imperfections. For me, it took 6 different sandings with 5-6 coats. I also

sprayed guide coat on in between these so I could tell when I took off what was

needed. This is what it should look like:

Once this is complete, it is now time to 500 wet sand. For this, just get your

500 sand paper and a bottle of water. This is just to make it smooth and PERFECT

for paint. This will also bring out any imperfections in your work. I then took

a scuff pad and did the whole bumper so it would be ready for paint. This is

what it should look like if you did it right:

And then the FINISHED product, oh, she's so majestic:

Zmods screen name:

My

Fairlady Z

3ZC screen name:

My

Fairlady Z

AIM screen name: saufen420

|