|

Cowl Grill Restoration |

Article Date: 07-27-08

Author:

Twisted

Six

Mod Class: Z32 All Models

Mod Type: Aesthetics

Article Origin:

Zmods.org

Difficulty Level:

3

(Scale of 1 to 10. 1 being extremely easy, 10 being extremely

difficult.)

Estimated Time to Complete: Approx 6 hours, allowing time between

coats, allow 48 hours of cure time before reinstalling.

Tools Required:

- 2 cans of black

Plasti-Dip Spray, available at Home Depot

- Various sandpaper grits, from 220 to 1000

- Heat gun or soldering iron

- Hot glue gun

- 1 can of flat black spray paint (optional)

- Fine tipped awl

- Acetone

or lacquer thinner

- Clean rags |

This procedure will restore your pitted and fading cowl grills to like new

condition. They must not be broken though. If they are, you're

better off finding a set that's not broken off a parts car to restore, as

there's no point doing this to a broken cowl. I did not cover removal and

reinstallation from the car in this writeup, as those steps are rather self

explanatory and extremely easy.

Getting Started

- Basic Prep

The set used for this writeup were from my 1994 Z32 Convertible, which had

sat outside for years. These were battered by the elements severely.

This car is a complete restoration in the works, so ignore the poor condition of

the rest of the car in some of these pics.

Here they are, removed from the car and ready to begin work on:

The first thing you want to do is to remove the rubber trim that goes between

the cowl and the windshield. It may have come loose when removing it from

the car, this is ok. Just set it aside for later.

Removing

the Screens

This is the part that can be a little tricky. I used a

surface mount rework station to do this, which blows super heated air to melt

solder for surface mount electronics. I know that most anyone reading this

won't have access to such a device, so in its place, I recommend a soldering

iron. The screens are originally held in place from the factory by melting

the plastic and placing the screen onto the melted plastic, allowing it to

harden, and holding it in place.

1) You simply need to heat the spots where the screens are

held in place to release the screen from the cowl.

2) While the plastic is heated, lift the spot where the screen

is attached with your awl. They really come off quite easily. Heat

and lift the screen off each spot, and that's that! Be careful not to snag

or disfigure the screens, as that can make reassembly more difficult. If

the screens don't come right off, don't force or bend them!! Reheat them

and try again.

Sanding the Cowls

In this step, you want to sand as much of the loose material off

the cowl as you can, including down in the grooves. I started with 220

grit, to smooth as much of the pitting as I could, and then moved up to 1000

grit to smooth it out as best I could. Depending on the degree of

degradation on your cowl, you may not be able to completely sand out all the

pitting without sanding it too thin or disfiguring the shape of the surface too

much. This is ok. The Plasti Dip will fill in any light sanding

marks and minor pitting, that's the beauty of this stuff! Unlike paint

prep, the surface doesn't need to be absolutely perfect, it will hide a lot of

blemishes.

Coating

Preparation

Now that you've got it all sanded and smoothed, you want to

clean the surface of contaminants so the coating will stick. I used

acetone, but lacquer thinner will work as well. Dampen a clean rag with

the acetone and wipe down all surfaces that will be coated. Be VERY

careful not to drench the plastic with the solvent, as it will eat away and

disfigure it if you do. Be conservative with this stuff, but make sure it

gets wiped down thoroughly! Once that is done, you want to lay

your cowls out to be sprayed. I stood them on boxes, and propped them up

with empty soda cans.

Applying the Plasti-Dip Coating

The time has come to apply the coating. You want to do

this in a similar fashion as you would if you were spray painting, applying the

coating in thin coats. Follow the instructions on the can for application.

Allow it to dry between coats. After the third coat, start making the

coats thicker as you go. I applied 6 coats, using 2 cans just on the

cowls. The cans don't last long, you'll go through them quicker than you

think. This stuff is thick, it's not like spray paint. This stuff

also stinks! I recommend wearing a respirator and doing this in a

ventilated area.

As the coating sets up, it will do strange things and look like

crap. Before you panic and think you made a mistake in your prep, let it

completely set up, which will take several hours. After coating it, I'd

just let it set overnight. When you look at it in the morning, it will

have smoothed out and set to a satin finish. You shouldn't need to apply

anymore coats unless you see a thin spot or other blemishes, which you shouldn't

if you took your time and coated it properly. The pics below are 6 coats,

cured overnight:

Preparing the

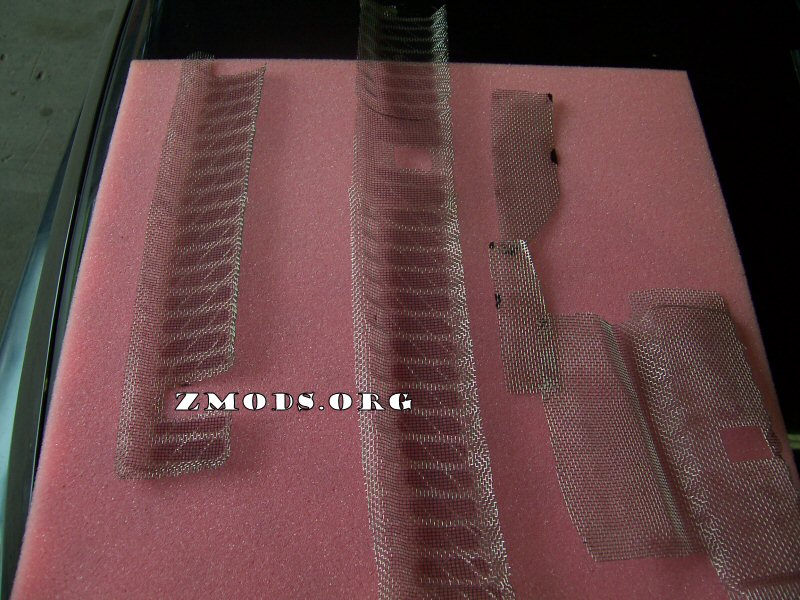

Screens for Paint

This step is optional, as you don't have to paint your screens.

I chose to do so, as it makes the whole thing come out a lot cleaner looking.

I washed the screens with hot water and simple green. Make

sure all debris, bug guts, leaves, and other crap is out of them!!! Dry

them thoroughly, I blasted them with an air compressor.

To prepare them for paint, wash them good with acetone or

lacquer thinner, and let them air dry, it won't take long, as it will evaporate

quickly. Then set them into position to paint.

Painting the

Screens

This step is also an easy one. I used some high temp flat

black I had left over from some calipers I painted. Give each side 3 thin

to medium coats of paint and allow them to dry. Don't overdo it with the

paint! If you coat them too thick, it will clog up the screens, and look

like crap.

Replacing

the Screens

You now want to round up everything and put it on a clean bench.

You'll need both parts of the cowl and all your screens, as the time has come to

reattach the screens to the cowls. You will also need your hot glue gun.

Plug it in and let it heat up while you round up all of your parts.

Flip the cowls upside down, setting them on a soft surface to

avoid scarring up the fresh plasti-dip coating. You'll want to test fit

the screens in their places and make sure they fit right, and that no

adjustments need to be made.

Once that's done, take the hot glue gun and dab each spot where

they were originally attached with some glue. DO NOT DO THEM ALL AT ONCE!!

Do each spot one at a time, applying the glue and then holding the screen in

place until the glue sets, which takes about 30 seconds. Then move on to the next dab, doing the same

thing. This stops the screen from lifting up or shifting around, insuring

that they reattach flush.

Replacing the Rubber Trim

Remember that rubber trim that was between the windshield and

the cowl that you removed early in the writeup?? Well it's time to replace

that piece now. There's not much to this, The groove on the rubber trim fits into the

lip on

the edge of the cowl. There's no need to glue it in place, just snap it

back into the groove. If it's loose, that's ok, it will be pinned between

the windshield and the cowl when you reinstall it anyway, so it won't go

anywhere. Just make sure it stays in place when reinstalling it on the

car. If you really want to glue it, you can, but there's no need to.

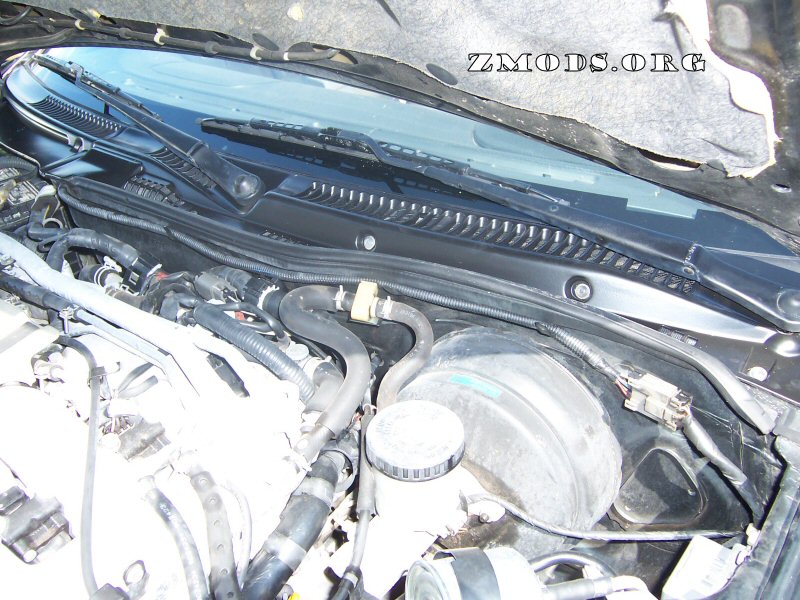

The Finished

Product

This is what it will look like after reinstalling it.

Please excuse these pictures, the car is dirty, the wiper arms are pitted, and I

didn't clean the dusty hand & finger prints from the cowls after the reinstall.

They really did come out amazingly though!!

I do hope you found this article useful!! I wanted to

extend my thanks to Greavous from 300zxclub.com for turning me on to Plasti-Dip,

this stuff is an absolute miracle in a can!!!

Back to Top

Zmods.org screen name: Twisted Six

3ZC screen name: Twisted Six

AIM screen name: TT2by2

|